Challenges for operators

Operators need to think about maintenance dates every year and find professionals to keep their slides in good shape. Bad experiences with unprofessional service providers are often inevitable. We take the stress away from you and offer an all-in-one solution.

Advantages of professional maintenance

- Aesthetics and visitor satisfaction: An attractive slide inspires visitors and prevents negative reviews.

- Durability and cost efficiency: Regular maintenance extends the useful life of the slide and saves costs.

- Legal safety: Compliance with the standards (DIN EN 1069-2) protects against legal consequences in the event of accidents.

- Comprehensive service: Concentrate on your core business while we take care of your slide.

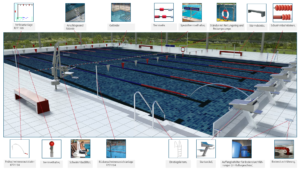

This is what the maintenance process looks like for many slide systems

- Plant Check:

- We comb through your plant, detect dangers in the bud and give you security and peace of mind.

- Steel structure inspection:

- Our experts inspect the steel structure and flanges of the slide elements, ensure stability and protect your investment.

- GRP preparation:

- We take care of imperfections, create flawless surfaces and minimize the risk of injury.

- Recoating:

- With color-matching topcoat, your slide shines in new splendor and ensures unforgettable sliding experiences.

- Joint renovation:

- We renew soft joints, guarantee long-lasting waterproofing and protect your facility from water damage.

- If necessary, reconditioning of the entire slide surface

- Many customers choose to have the entire slide surface refurbished and sealed for improved appearance and longevity, so that it shines again in new splendor and can better withstand wind and weather.

Contact us for a non-binding offer!

Send us photos and information about the current condition of your slide, if available the result of the current TÜV test, or let us come in person. Together we will find the best solution for you!

vertrieb@roigk.de

Why do I have to wait a slide?

According to DIN EN 1069-2, you must have your large water slides (type 3-10) serviced by a specialist company at least once a year. Here, the standard places particular emphasis on, for example:

- Lifespan

- Components inspection

- Inspection intervals and procedures

- Care of materials such as, steel construction, stainless steel and GRP

- Debris removal

A maintenance is not a TÜV acceptance! How does a TÜV test according to DIN EN 1069 take place?

- Test period: Water slides must be tested annually by an independent body such as TÜV. A slip test is required every three years. Operators should additionally perform daily visual inspections and periodic inspections.

- Test object: Inspections focus on damage-prone areas such as slip surfaces, joints, stability and signs of wear. The annual inspection also includes checking the water flow rate to prevent accidents or injuries.

- Inspection record: inspectors document findings, including potential deficiencies and safety concerns. If there are concerns, the slide will be shut down until the operator corrects the deficiencies. A new test decides on the release of the plant.

After our service, you can look forward to the annual safety inspection by TÜV without any worries.

For which types of water slides is the maintenance service recommended?

Whether it is water slides for outdoor or indoor pools, toddler slides, wide wave slides, open or tube slides made of GRP (glass fiber reinforced plastic or polyester) – we can assist you with all of them. This applies, for example, to public swimming pools, water parks and slide parks.

Is a long-term maintenance contract mandatory?

You can also order a single repair. Nevertheless, we recommend annual inspection and maintenance service to ensure the longevity of your system and keep costs low.